What is metal extrusion?

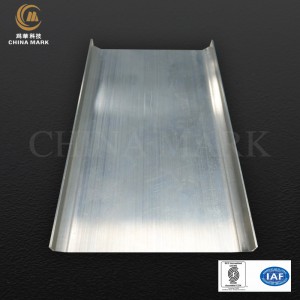

Aluminum extrusion process

Metal extrusion processing is an important method of pressure processing based on the principle of metal plastic forming.Metal extruder is the most important equipment for metal extrusion.

Extrusion is one of the main methods for the production of nonferrous metals and iron and steel materials and the forming of parts. It is also an important method for the preparation and processing of various advanced materials such as composite materials and powder materials.

From hot extrusion of large-sized metal ingot, hot extrusion of large-sized tubular bar profiles, cold extrusion of small-sized precision parts, direct solidification and molding of composite materials with powder and particle materials as raw materials, to difficult processing materials such as intermetallic compounds and superconducting materials, modern extrusion technology has been widely used.

Extrusion processing methods are mainly positive extrusion, reverse extrusion, lateral extrusion, glass lubrication extrusion, hydrostatic extrusion, continuous extrusion.Extrusion processing is characterized by a strong three-way compressive stress, which is conducive to improving the plastic deformation capacity of the metal, improving the quality of the product, improving the internal microstructure and performance of the product.

In addition, extrusion processing also has a wide range of applications, production flexibility, simple process and less equipment investment.

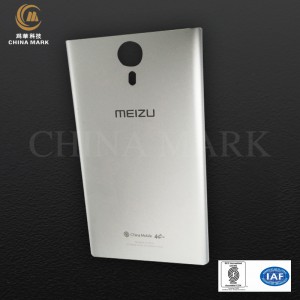

Non-ferrous alloys with low melting point, such as aluminum and aluminum alloys, are the most widely used materials in extrusion processing.

Aluminum Extrusion Manufacturers