Introduction of aluminum extrusion molding die, advantages and disadvantages | WEIHUA

One trend we see is that aluminum or aluminum extrusion is more and more used in various industries. The use of aluminum extrusion can achieve an unexpected cost reduction and weight reduction.

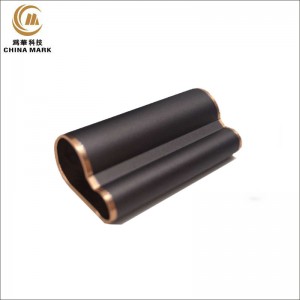

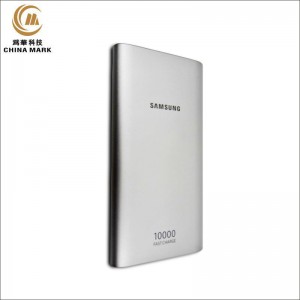

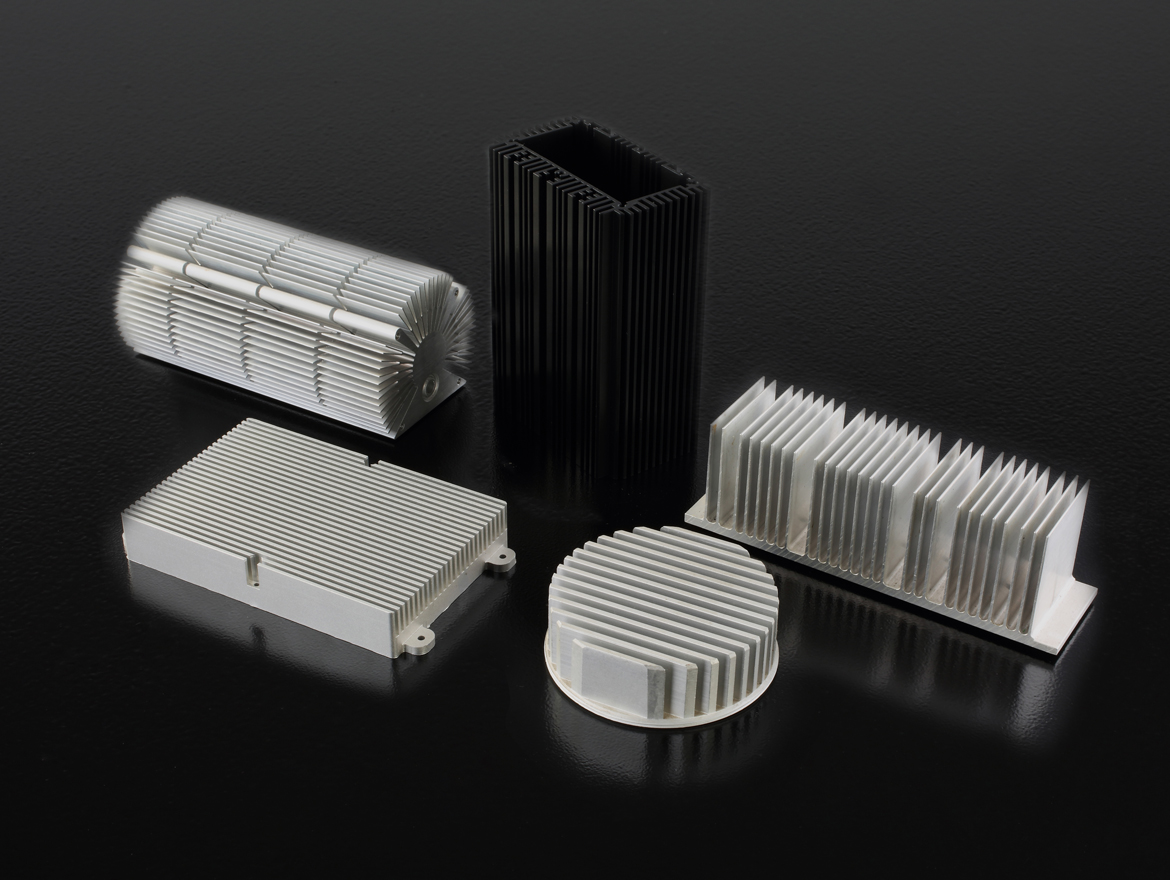

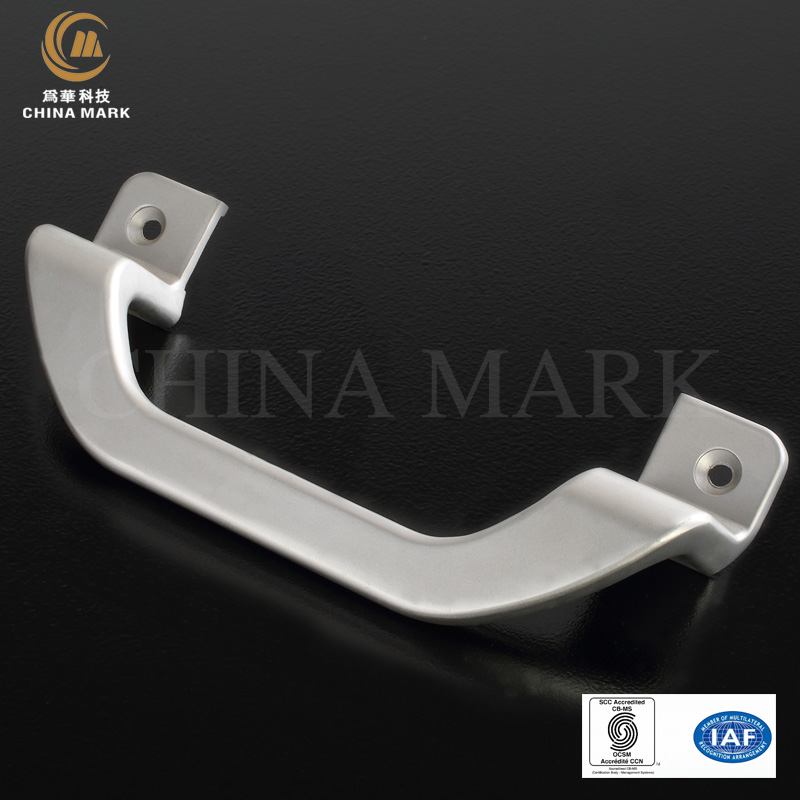

Only by fully understanding the process, dies, characteristics and applications of aluminum extrusion can we design aluminum extrusions (aluminum extrusion shells, curved aluminum extrusion products, aluminum extrusion electronic cigarette shells, aluminum extrusion power supply shells, aluminum extrusions, Press cell phone shells, aluminum extrusion computer shells, aluminum extrusion radiators, etc.) to ensure high quality and low cost of aluminum extrusions.

01

Definition of aluminum extrusion process

Aluminum extrusion molding (or aluminum extrusion molding) is to apply strong pressure to the aluminum billet placed in the die cavity (or extrusion cylinder) to force the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion die. In order to obtain the required cross-sectional shape, size and certain mechanical properties of the part or semi-finished plastic processing method.

02

Aluminum extrusion die

For product structure design engineers, although we will not design aluminum extrusion dies, we know the most basic extrusion die structure and the mechanism of how to form different extrusion profiles, which helps to optimize the design of extrusion parts. Reduce mold costs and improve the production efficiency of extruded parts.

2.1 What is an extrusion die?

The extrusion die is basically a thick circular steel disc, including one or more openings to form the desired profile. They are usually made of H-13 die steel and have been heat treated to withstand the pressure and heat of the hot aluminum as it passes through the die.

Although aluminum looks soft, pushing a solid aluminum ingot (blank) through a thin porous aluminum extrusion die to form the desired shape requires a lot of pressure.

2.2 Classification of extrusion dies

According to the cross-sectional shape of aluminum extrusions, the corresponding molds are divided into three types: integral, semi-hollow, and hollow. Among them, the hollow mold has the most complicated structure, is easy to wear and break, and has the highest cost.

2.3 The life of the extrusion die

When designing aluminum extrusions, heat accumulation and uneven pressure (such as thin wall, non-uniform wall thickness, and prominent features) are the biggest killers of extrusion die life.

Professional extrusion mold engineers can design molds to control hot pressing and non-uniform pressure, reduce the extrusion speed to extend the life of the mold, but eventually the mold must be replaced.

Before designing aluminum extrusions, product structure design engineers should understand which design features will most significantly affect mold processing costs. When possible, changing the design of the section of aluminum extrusion parts, setting appropriate tolerances, and selecting appropriate aluminum alloy materials can save the processing cost of aluminum extrusion molds.

03Advantages of aluminum extrusion process

1) Durable

The corrosion resistance, corrosion resistance and weather resistance of aluminum is one of its most significant advantages. Aluminum can rust naturally and resist corrosion without additional treatment. This is due to the presence of a thin, naturally formed protective film of aluminum oxide on its surface. By anodizing, its corrosion resistance becomes stronger.

For example, in an outdoor environment, 25-micron anodizing can enhance corrosion resistance and improve surface finish. In addition, aluminum does not require maintenance, and in most cases there is no need to worry about corrosion.

2) Lightweight and strong

Aluminum is more than 33% lighter than steel, but still retains most of its strength. The tensile strength of most aluminum alloys is in the range of about 70-700 MPa, and the density is two-thirds less than that of steel.

Product design engineers don’t need to worry about the strength of aluminum extrusion parts. They can be used as structural parts in the construction industry and the automobile industry, and are the best substitutes for other metal materials. In order to reduce weight and reduce energy consumption, the automotive industry has largely used aluminum alloys.

3) Good thermal conductivity

The thermal conductivity of aluminum is very similar to copper, but the weight is much lighter.

Aluminum is an excellent heat conductor, and the profile design of aluminum extrusion can maximize the surface area of heat conduction and form a heat channel. A typical example is a computer CPU heat sink, and aluminum is used for CPU heat dissipation. Aluminum extruded radiator is the best product to use.

4) Fashionable appearance

Extruded aluminum can be painted, electroplated, polished, and anodized, which gives engineers a wider choice of appearance than other materials. Example: Aluminum extrusion handle

5) Wide application range

Basically, any cross-sectional shape can be formed by aluminum extrusion, so the application range of aluminum extrusion is very wide. Engineers can design different sections to meet the requirements of different application environments.

6) Easy secondary processing

Aluminum extrusions are easy to form, cut, drill, process, stamp, bend and weld to suit specific purposes. For example: aluminum extrusion rails, etc.

7) Short mold processing cycle and low cost

The aluminum extrusion die is simple, the processing cycle is short, and the cost is low. This is a comparison between AEC aluminum extrusion and other processes, for reference only.

8) Absorb impact and deformation

Aluminum extrusions are resistant to deformation caused by weather and construction movements. Vehicles can absorb impact energy. Aluminum extruded parts maintain strength and flexibility under load and rebound from impact. For example: the use of automotivealuminum extrusions. The use of automotive aluminum extrusions can absorb impact energy

9) Environmental protection

Aluminum is an environmentally friendly material and easy to recycle.

After sorting and sharing the above articles, we now have an understanding of aluminum extrusion, aluminum extrusion products, aluminum extrusion numerical control, aluminum extrusion molds, etc. China weihua provides professional aluminum extrusion, industrial aluminum extrusion, aluminum Customized processing of products such as extruded signs and aluminum extruded enclosures. Please pay attention to our homepage https://www.cm905.com/.